Solar photovoltaic technology basics

Silicon solar cells

Thin-film solar cells

III-V solar cells

Next-generation solar cells

Fill out the application

Solar photovoltaic technology basics

Silicon Solar Cells

The vast majority of today’s solar cells are made from silicon and offer both reasonable prices and good efficiency (the rate at which the solar cell converts sunlight into electricity). These cells are usually assembled into larger modules that can be installed on the roofs of residential or commercial buildings or deployed on ground-mounted racks to create huge, utility-scale systems.

Thin-Film Solar Cells

Another commonly used photovoltaic technology is known as thin-film solar cells because they are made from very thin layers of semiconductor material, such as cadmium telluride or copper indium gallium diselenide. The thickness of these cell layers is only a few micrometers—that is, several millionths of a meter.

Thin-film solar cells can be flexible and lightweight, making them ideal for portable applications—such as in a soldier’s backpack—or for use in other products like windows that generate electricity from the sun. Some types of thin-film solar cells also benefit from manufacturing techniques that require less energy and are easier to scale-up than the manufacturing techniques required by silicon solar cells.

III-V Solar Cells

A third type of photovoltaic technology is named after the elements that compose them. III-V solar cells are mainly constructed from elements in Group III—e.g., gallium and indium—and Group V—e.g., arsenic and antimony—of the periodic table. These solar cells are generally much more expensive to manufacture than other technologies. But they convert sunlight into electricity at much higher efficiencies. Because of this, these solar cells are often used on satellites, unmanned aerial vehicles, and other applications that require a high ratio of power-to-weight.

Next-Generation Solar Cells

Solar cell researchers at NREL and elsewhere are also pursuing many new photovoltaic technologies—such as solar cells made from organic materials, quantum dots, and hybrid organic-inorganic materials (also known as perovskites). By coating a traditional silicon cell with a mineral called perovskite, scientists develop more efficient tandem solar cells that greatly increase efficiency.

Latest Solar PV Cell Technologies

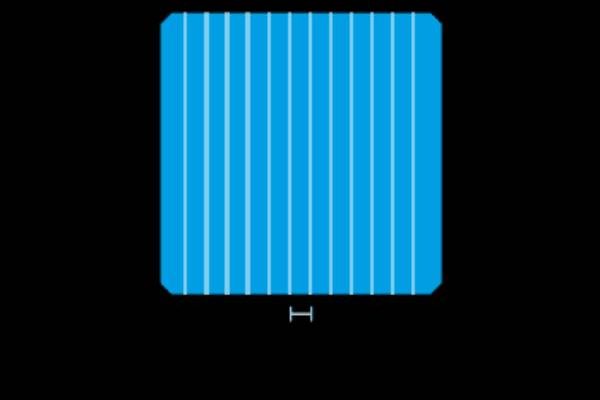

Most panel manufacturers offer a range of models including regular entry-level options and more advanced high-efficiency varieties featuring new technologies such as high-density cells, micro-wire busbars and rear-side passivation. Below is a list of the leading PV cell technologies used today:

- HJT – Heterojunction cells

- TOPCon – Tunnel Oxide Passivated Contact

- Gapless Cells – High-density cell construction

- PERC – Passivated Emitter Rear Cells

- Multi Busbar – Multi ribbon and micro-wire busbars

- Split cells – half-cut and 1/3 cut cells

- Shingled Cells – Multiple overlapping cells

- IBC – Interdigitated Back Contact cells

Heterojunction (HJT) technology

Heterojunction (HJT) technology was overlooked for many years, but it has been taking momentum for the last couple of years, showing its true potential. HJT solves some common limiting factors for standard photovoltaic (PV) modules, like reducing the recombination process and improving performance in hot climates. There are three important materials used for HJT cells:

Crystalline Silicon (c-Si)

Amorphous Silicon (a-Si)

Indium Tin Oxide (ITO)

Crystalline silicon is regularly used to create standard homojunction solar cells, seen in conventional panels. There are two varieties of c-Si, polycrystalline and monocrystalline silicon, but monocrystalline is the only one considered for HJT solar cells since it has a higher purity and therefore more efficient.

Gapless Cells technology

South Korean PV module manufacturer Q-CELLS and Austrian PV module manufacturer Energetica producing solar modules based on gapless technology, which raises the density of panels by eliminating the empty spaces between the cells. This technology achieves higher module efficiency as cell gaps are eliminated in strings.

Shingled Cells technology

A solar panel manufacturing process that has gotten some traction recently is “shingling.” Not to be confused with “solar shingles” used in building-applied photovoltaics, shingled modules cut solar cells into strips and overlap them inside the framed module. Intercell gaps are removed, and more silicon cells can be crammed into one module, increasing power output and module efficiency.

Shingled modules are likely the rightmost limit of crystalline silicon solar development. Without the introduction of dual-junction processes, like with heterojunction technology, which combines crystalline silicon with amorphous silicon thin-film to produce a high-power hybrid cell, a shingled module is the highest power and efficiency you can get with traditional, undoped crystalline silicon.

IBC - Interdigitated Back Contact cells

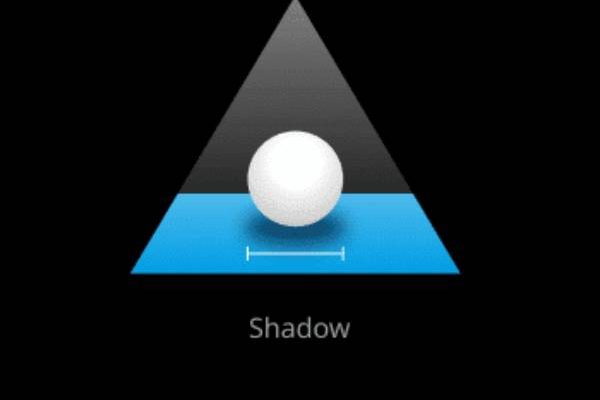

Interdigitated Back Contact (IBC) cells may be one of the most complicated technologies used to fabricate solar panels, but it also offers efficiency values that cannot be ignored, which is why it is considered an important alternative today.Traditional solar cells achieve energy conversion by placing front contacts in the cell. This means photons that reach the surface of the cell must be absorbed at that moment to release electrons and produce electricity.If they are not absorbed they are transmitted or reflected. This can be considered a loss.IBC cells implement a different idea. Instead of placing the contacts in the front of the cell, they place them on its rear side.This allows them to achieve higher efficiency due to reduced shading on the front of the cell, while at the same time electron-hole pairs generated by the absorbed light can still be collected on the rear side of the cell. On the illustration below you can take a look at the structure of IBC cells, from a rear side point of view.

Other technologies to pay attention to.

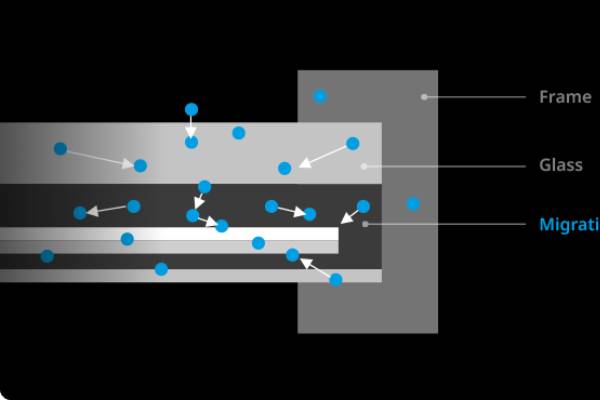

Anti PID Technology

Potential Induced Degradation can lead a significant power loss on both P-type and N-type cells, so the APT effectively protects the solar cells and secures high energy yield in the long-term.

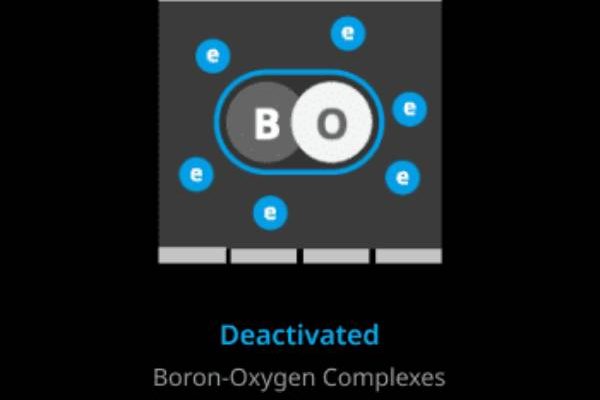

Anti LeTID Technology

Light and Elevated Temperature Induced Degradation (LeTID) effect can significantly damage the power of solar cells on both p-type and n-type cells. Q-Cells is the first company to observe LeTID effects and come up with a solution to suppress LeTID.

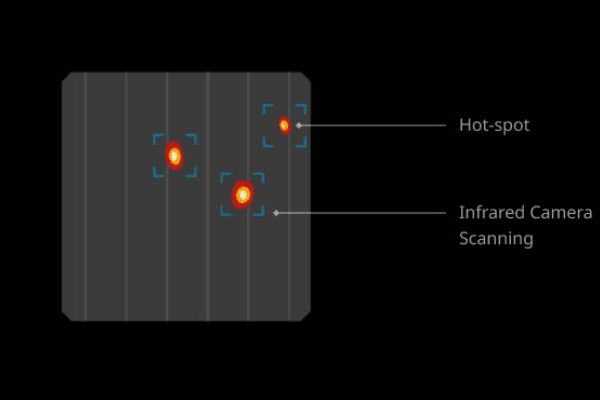

Hot-spot Protect

One hotspot can cause a continuous loss of yield and in the worst case, the module can ignite. To prevent hotspots from forming in the cells, the manufacturer tests solar cells in various ways, such as by scanning the infrared camera.

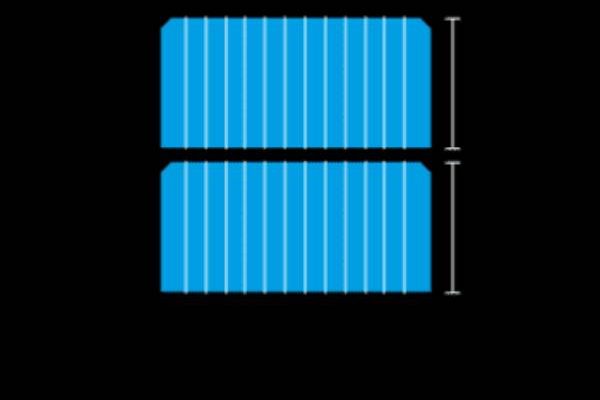

Half-cell Technology

Greater output by halving the current

Halving the cell halves the current. When combined with a module layout which reduces the distance traveled by the electric current, the result is a 3% increase in power. Two half cells with 12 busbars have the same or even greater output as a full cell with 24 busbars.

Multi Busbars Technology

Less resistance and better capture of excited electrons

Reduced distance in between the busbars and additional paths for electric current results in 2% power increase. More paths can be created with the shorter distance leads lower congestion, which in turn reduces resistive losses.

Wire Interconnection

Reduced shading losses with round wires

Utilizing wires instead of flat ribbons reduces both the width and the effective shading width decreasing shading by 75% and increasing the power by 2.5%. The light reflected from the round shape of the wires improves the light capturing effect of the module.